Parts Handling Conveyors

Titan ConveyorsTM has a conveyor solution for moving and elevating all types of parts including small delicate parts, bulky awkward parts, and heavy metal parts. Typical industries include injection molding, candy making, fastener manufacturing, stamping, and die casting.

When Titan designs a parts conveyor for you, it will be exactly what you need, without compromise. It will have the dimensions and features to adapt the conveyor perfectly to the application.

Challenge and Solution

A candy manufacturer needed to keep pieces of different colors separate while elevating them up an incline to the next step in the process. Having a separate conveyor for each color would have taken up too much space and been costly. Titan designed a multi-lane plastic belt conveyor with a horizontal section for loading, and incline section for elevating, and a nose-over horizontal section for discharging to product the next step in the process. By combining lanes into a single conveyor the customer saved space, money, and maintenance. The project was successful and the candy company became a long time partner with Titan for all their conveying needs.

Typical Types of Conveyor Used in Parts Handling:

- Model 102 Low profile for removing parts or scrap in narrow openings

- Model 350 Pro Feed for conveying parts out of hoppers

- Model 304 and Model 310 cleated belt conveyors for parts that need to be handled gently

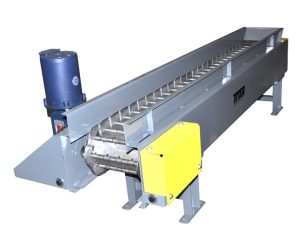

- Model 620 for the fastener industry, when metal parts cannot afford to be pinched during processing

- Model 630 for large stamping and die cast parts

- Plastic Belt Conveyors – Titan Engineering capabilities can design a plastic belt conveyor that will suit your parts handling needs.