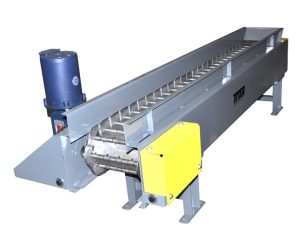

Stamping Plant Conveyors

For over 30 years, Titan ConveyorsTM has provided a complete line of heavy duty conveyors to move material in stamping operations. Whether you are handling work in process, finished parts, or scrap; there is a Titan conveyor to handle any piece from the size of a dime to the size of a car.

You will not find a more robust conveyor on the market, thanks to Titan’s special features, only a few of which are mentioned here.

- Only Titan has our exclusive radial sidewing to keep material confined on the belt and out of the frame where it causes harm. This feature is found on ALL hinged steel belt conveyors from 2-1/2” pitch to 6” pitch.

- All Titan models make maximum use of welded construction.

- The model 660 and 640 utilizes flanged rollers for solid belt control.

- The belt track of the model 660 consists of a 25# rail for durability and to keep material off the track.

- An almost infinite number of features and options that customize your conveyor to the application for maximum durability, ergonomics, and convenience. Even simple things like a clean-out window in the frame can make a major difference in your operation.

Typical Types of Conveyor Used in Stamping Plants:

- Model 620 with a close tolerance radial side wing for small fine parts. This model is known to prevent damage to parts seen with typical hinged steel belt conveyors

- Model 630, our workhorse 2-1/2” pitch for larger stamping and die cast parts

- Model 640 and 660 hinged steel belt conveyors for very large parts and parts weighing many pounds and for parts being loaded with force

- Model 350 Pro Feed for elevating conveying parts dumped into its integrated hopper

- Model 102 low profile conveyor, a tough press conveyor that fits in tight spaces. The model 102 does the job at half the cost of similar conveyors on the market with extruded aluminum frames

To request a quote, click here.