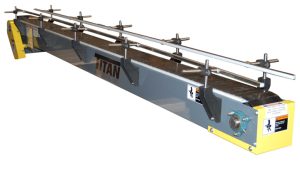

Candle Making Industry Conveyors

Titan ConveyorsTM is a leading supplier of conveyors to the Candle Making Industry. Most commonly, these conveyors are standard or customized versions of the Titan Model 124, wire mesh belt conveyor. We offer special features unique to the industry such as extremely slow moving belts for cooling and pitched drip collection pans for mounting underneath conveyors. Titan is able to make unusually wide and long conveyors as “standards”, which will save your project time and money. Other common features include lane dividers, product crowders, and diverters.

Challenge and Solution

A maker of specialty candles was looking for a combination filling and cooling line to fit a small space. The line was to be operated with very few personnel. In addition, the conveyor needed to run in reverse at times. Titan engineers created a dual belt wire mesh conveyor with the belts running in opposing directions, while utilizing a common head and tail shaft in a single frame structure. Each belt had its own center drive with individual speed control and was reversible. Titan also provided a custom structure for the end user to mount their filling equipment.

Typical Types of Conveyor Used in Parts Handling: