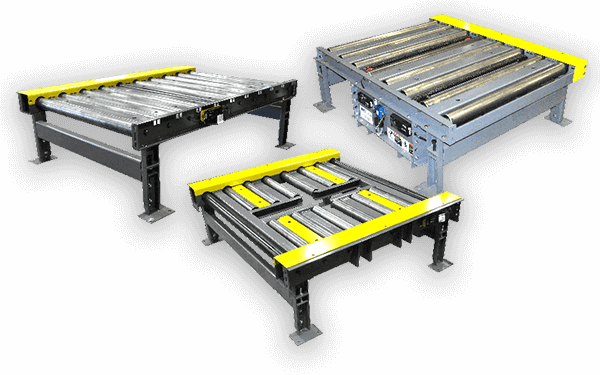

Motor-Driven Roller Conveyors (MDR)

Titan ConveyorsTM introduces the Motorized Roller Conveyor, a modular conveyor system utilizing a 24 volt DC drive within a roller. Adjacent rollers are powered from it using either chains, poly V-Belts or urethane O-belts. Motorized roller systems are perfect for large zone controlled systems in assembly lines, warehouse situations or unit handling of pallets, totes and cases. Loads up to 3,900 lbs. can be moved with these clean and efficient motorized roller systems.

Operational Advantages of Powered Roller Conveyors

- Reliable

- Flexible – built in variable speed

- Clean

- Real zero-pressure accumulation

- Low energy use

- Plug and play controls

- No awkward motor & gearbox

Operator Advantages

- Low noise improves work environment

- Low torque – improved safety

- No sprockets reduce pinch points

- Reversible – dynamic braking

Maintenance Advantages

- Few spare parts

- Relatively maintenance free

- Low cost repair parts

- Short repair times

- Most repairs can be done by a single person