Machine Tool Chip Conveyors Built for Durability and Performance

Since 1981, Titan Conveyors has been a leading manufacturer of chip conveyors specifically designed for metalworking operations. Our signature innovation is the exclusive tight tolerance Radial Sidewing, which eliminates the common problems that plague traditional scrap chip conveyors.

Here’s how Titan chip conveyors outperform the competition:

- Eliminates Jams and Belt Damage: Our Radial Sidewing design prevents material scrap carry back and seepage into the return track, significantly reducing jams and protecting your belt from wear and tear.

- Superior Wear Resistance: Titan chip conveyors feature tough 10 gauge frames and all-welded construction for unparalleled durability.

- Unmatched Versatility: We offer a wide range of standard and custom chip conveyor solutions to meet your specific needs.

Don’t settle for just any chip conveyor. Choose Titan for unmatched performance, reliability, and value.

Challenge and Solution: Machine Shop Benefits from Chip Conveyor

A machine shop producing a high volume of chips continuously could not shut down the chip scrap conveyor to change bins. Titan offered a discharge chute with a pant leg configuration and a pneumatic diverter to shift the flow of chips from one side of the pant leg to the other.

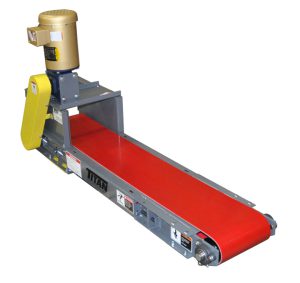

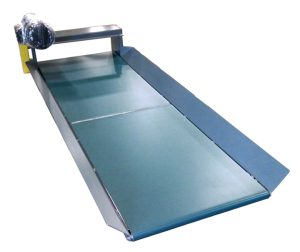

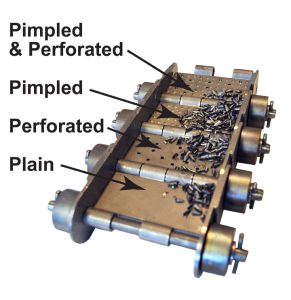

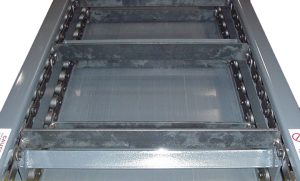

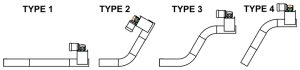

Conveyors are available with either a stamped side wing or our exclusive radial side wing which virtually eliminates jamming with small chips and fines. Chip conveyor models are available with many options including drive locations, liquid tight bottom pan. Typical models used for chip conveyors:

- Model 102 low profile slider bed for the very narrowest of spaces is required

- Model 610 when the in-feed requires the lowest possible profile

- Model 620 for most applications

- Model 670 Drag Chain Conveyor is the choice for carrying cast iron, fine chips, sludge and scrap that would normally jam a hinged steel belt unit.