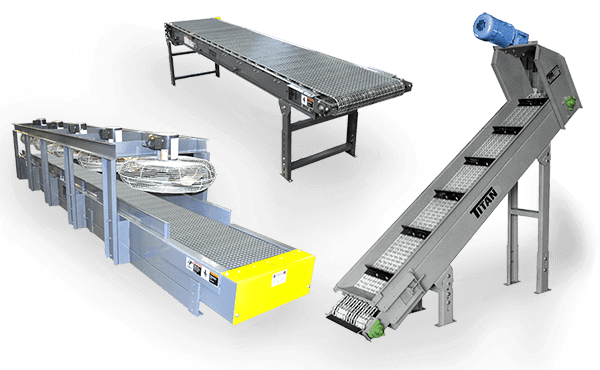

Wire Mesh Belt Conveyors

Depending on loads and installation, Titan offers two models with a variety of wire mesh configurations and three different bed materials – UHWM plastic, roller or wear strip slider.

- Model 124 is a multi-functional load carrier for drying, cooling, or moving hot parts. It’s available with two deck styles: roller bed and longitudinal. Numerous optional belt types are available. Can interface with existing conveyor systems.

- Model 305 is a heavy-duty incline flat wire mesh conveyor that’s ideal for heat-treated, washed, dried, or quenched parts. High side rails and completely enclosed bottom pan.

- Cooling & Drying Conveyors are designed to interface with existing conveyor systems and are custom engineered from standard components. Increases die casting efficiencies by eliminating mist and replacing water quench. Reduces cool down time.