Appliance Manufacturing Conveyors

Titan ConveyorsTM has been supplying conveyor systems to appliance manufacturers in North America for over 25 years. Our knowledge and understanding of key success factors in the appliance industry can help you meet your challenging ergonomic and productivity objectives quickly and easily. No other conveyor manufacturer offers the extensive portfolio of features, options, and customization to ensure the optimal solution. Plus, Titan has the unique ability to provide both custom and standard conveyors, so you never pay for more than you need.

Titan offers a conveyor model to handle material at the start of the process in stamping and die cast operations through the assembly line and final packaging. And, with our focus on conveyors for the rigors of industrial applications, you can rest assured that every machine we build is designed for around the clock operation.

Challenge and Solution

A manufacturer of large appliances was having difficulty on the assembly line inserting screws near the base of the appliance due to interference with the chain guard on their current powered roller conveyor. Titan designed a powered roller conveyor with very low profile guarding. Perhaps most importantly, the change was a modification to a standard design, which kept the cost and delivery in line.

Typical Conveyors Used in Appliance Manufacturing:

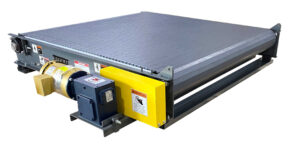

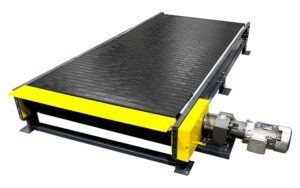

- Hinged Steel Belt conveyors for part and scrap handling

- Incline parts conveyors and plastic belt conveyors for parts handling

- Slider bed belt conveyors for movement of light and irregularly shaped

- Multi-Strand Chain conveyors for heavy appliance assembly lines

- Zoned Powered roller conveyor, turntables, pop up transfers and multi-strand chain conveyor for heavy duty assembly line systems

- Pallet pro for assembly lines with walk on requirements

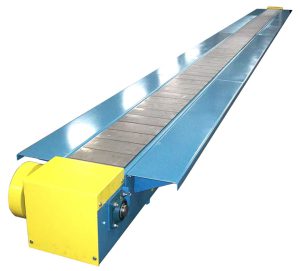

- Table top conveyor for light assembly operation’