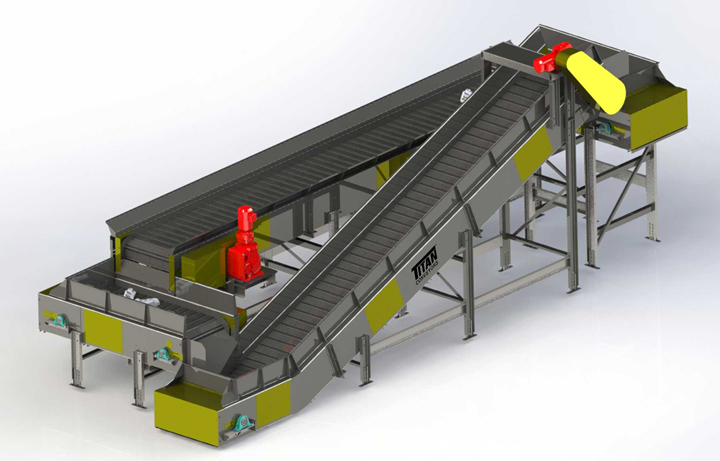

Foundry Industry Conveyors

No industry presents a more challenging environment for conveyors than foundries. Titan ConveyorsTM, with our focus on heavy duty industrial conveyors and wide range of models, can provide solutions throughout your foundry operations. We listen carefully to the demands of the application, so your conveyor is designed from the start to hold up to the task. Something as simple as understanding exactly how the product is loaded onto the conveyor can make the difference in whether the conveyor lasts one year or twenty years.

Challenge and Solution

After casting in sand, the mixture and consistency of the material in the discarded mold presents a great challenge. Titan offers its model 340 corrugated sidewall conveyor as fail-safe solution. The model 340 confines the material being conveyed to discreet compartments molded into the belt. With the material being fully confined, the material can be hard, soft, granular, dry, damp, clumpy, chunky, or any mixture of those. The model 340 is truly a unique solution.

Typical Conveyor Used in the Foundry Industry:

- Extreme duty slider beds for moving casting through work stations

- Roller bed belt conveyors to reduce to reduce friction when possible

- Heavy duty chain driven live roller conveyor and multi strand chain conveyor for moving pallets of finished product

- Heavy duty chain driven live roller conveyor, heavy duty multi strand chain conveyor, chain transfers, and turntables for moving bins of work in process

- Trough belt conveyors and corrugated sidewall belt conveyors for moving waste products

- Hinged steel belt conveyors for elevating metal products